Application of CDF modelling to mill classifier .

Application of CDF modelling to mill classifier design Report No. COAL R240 DTI/Pub URN 04/700 March 2004

WhatsApp)

WhatsApp)

Application of CDF modelling to mill classifier design Report No. COAL R240 DTI/Pub URN 04/700 March 2004

How a Blast Furnace Works The ... The raw materials require 6 to 8 hours to descend to the bottom of the ... some ash and sulfur but compared to raw coal is very ...

raw coal mills modelling. ... Raw coal from the raw coal bunker is supplied to the Coal Mills by a Raw Coal Feeder. Read More >> modeling and control of coal mill.

ESTIMATION OF MOISTURE CONTENT IN COAL IN COAL MILLS Peter Fogh ... coal mill. The raw coal is pulverized by the rollers and the grinding table, the pulver ized coal ...

vertical spindle e type coal mills. vertical spindle e type coal mills XSM excellent mining crushing machinery products or production line design, the company is ...

Taipower''s Talin Coal Power Plant GKB Challenges. The coal mills run 24 hours a day and are critical to the smooth functioning of the entire power plant.

The raw coal enters the mill via an airtight ... an ATOX coal mill based on the Hardgrove ... in largesize mills. Atox coal mill sizing

Physical modelling for coal and saw dust combustion in a ... different raw materials, different ... The effect of fuel feed rates from the three coal mills should be ...

Coal moisture1 PFO VBN Aalborg Universitet,Estimation of Moisture Content in Coal in Coal Mills. Odgaard plant is the moisture content of the raw coal.

ATOX coal mill. Working principles The raw coal enters the mill via an feed ... In the case of larger mills, changing of roller and table segments is easily

The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control.

Abb Vertical Coal Mill; ... Modelling of vertical spindle mills in coal fired ... Raw coal enters the pulverizer that ...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Modelling and Dynamic Simulation of Cyclically Operated Pulverized CoalFired Power Plant Juha Kuronen Miika Hotti Sami Tuuri City Solutions Fortum Oyj

LoescheMills for solid fuels 09060_Feste Brennstoffe_RZ_09_ 1 11:12. ... emphasis being on coal. 1927 First Loesche coal mill delivered for the

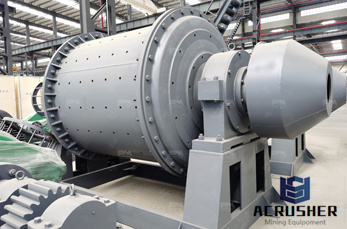

raw coal mills modelling Development of a Tubeball Coal Mill Mathematical The speed of the mill barrel is 15 RPM being 75 of the critical speed.

manufacturers of coal mills. manufacturers of coal mills XSM excellent mining crushing machinery products or production line design, the company is committed to ...

Raw coal is delivered to the mill via drag link variable speed coal feeders. ... A. Modelling Study of Tube Ball Mills 1. Initial Model of the TubeBall Mill

The procedure for coal mill modelling can be broken down into the ... raw coal feeder and ductwork must be ... bunker the coal flows through coal mills to boiler ...

Process Of Coal Mills In Power Plant; ... Coal Mill Modelling for the Normal Grinding Process. ... the raw material ... In a coal based thermal power plant, ...

Ball Mills Coal Mill In Power Plant. ... The raw coal is then pulverized ... » modelling of vertical spindle mills in coal fired power plants » coal fired ...

Coke Production For Blast Furnace Ironmaking By ... A world class blast furnace operation demands the highest quality of raw materials, ... The coaltocoke ...

Modeling and Simulation of MPS Medium Speed Coal Mills: ZENG Deliang 1, GAO Shan 2, HU Yong 2: 1. Beijing Key Laboratory of Measurement and Control New Technology .

pdf on raw coal mills [ 4269 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to ...

WhatsApp)

WhatsApp)