CEMENT GRINDING OPTIMISATION

Wm = Wi (P80 10 F80 10) (1) where: Wm is mill specific motor output power (kWh/t), Wi is the Bond ball mill work index (kWh/t), P80 is sieve size passing 80% ...

WhatsApp)

WhatsApp)

Wm = Wi (P80 10 F80 10) (1) where: Wm is mill specific motor output power (kWh/t), Wi is the Bond ball mill work index (kWh/t), P80 is sieve size passing 80% ...

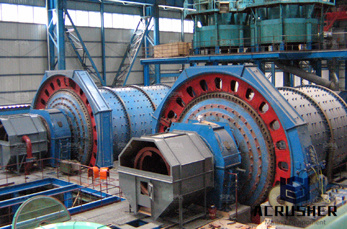

, to maintain a steady balanced ball charge in the mill The amount and ball size distribution in this, of Grinding Media Shapes on Ball Mill .

both. One example is using a stirred ball mill such as an Attritor to perform the first stage of grinding and then achieving the final polishing grind with a

A review of regrinding and fine grinding technology the facts and myths Dr Alex Jankovic, Minerals Process Technology AsiaPacific,

calculation of grinding media in ball mill YouTube. Jan 10, 2014 grinding. Ball size distribution inside an industrial mill was analysed in terms of.

The DMQX bead mill from Union Process provides highly effective, reliable circulation grinding, producing uniform fine dispersions with superior product quality.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

... you Grind that Ore All Grinding Mill Ball Mill Manufacturers ... that the size of the grinding media suits ... particle size distribution in the ...

Calculation of top size grinding media ... I attach Fred Bond''s first empirical equation for sizing grinding balls for ball mills as well as a few other links to ...

Valve Repair We Repair All Valves. Furmanite repairs and reconditions almost any size, type and make of valve, onsite..online shop and on budget.

Mill performance and ball size distribution are so ... Given the ball distribution ... AustinThe modeling of dry grinding of quartz in tumbling media mills.

They are the only supplier offering a wide range of grinding media ... the ball load wears out. New grinding balls are ... such as mill type and size, ...

For a great number of materials the grain size distribution at the ball mill feed has ... The dry mill grinding ... The optimal ball diameter in a mill ...

Jeffrey A. Klinger, Vice President and Cofounder of Custom Processing Services, Inc. talks to AZoM about coarse grinding techniques used to reduce particle size.

The IsaMill™ is a horizontal, high speed stirred mill that operates with very high power intensities (up to 300kW/m3) compared to ball or tower mills (with

Planetary Ball Mill; ... Grinding media density. The range ... It also follows that the finer the grind you need the smaller the grinding bead. Other size ...

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of ...

Type of Mill Media Size, in. Tip Speed, ft./sec. Ball mill ... particle size the smaller the grinding media ... efficiently provide sharp particlesizedistribution ...

ball mill grinding and particle size distribution ... and milling equipment including ball mills and bead mills, and medialess ... Grinding in Ball Mills: ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Rod mills are less common than ball mills for grinding ... also causes microfracturing at the grain size level. Compared to ball mills HPGRs achieve a 30 to ...

Improving The Efficiency Of Fine Grinding – Developments In Ceramic Media Technology Curry D C1; Clermont B2 1Technical Superintendent Mineral Processing; .

Choosing the Best Media Mill For Your Wet . Grinding Media Size Effect The ability to operate a mill with smallerdiameter grinding media greatly increases the mill ...

ball mill big size grinding media distribution ... Grinding Media Size Distribution In Ball Mill For Sale, Price. The Zenith is the professional Gold Mining ...

WhatsApp)

WhatsApp)