raw mill blending cement for bauxite crushing process ...

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

WhatsApp)

WhatsApp)

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

Raw Mill In Cement Plant,Cement Making Plant ... Stock Pile, Raw Material Hopper, Blending Storage Silos, Raw Mill, Raw Mill Foundation, Heat Exchanger Building, ...

Homogenization Strategy in the Cement ... The PreBlending Stockpile is sometimes used as a ... The battery of feed bins for the raw mill consists of one large ...

The raw material preparation stage of cement manufacture results in the ... system and an elaborate blending ... weighing of raw materials at the raw mill.

On Jun 1, 2004 Ayhan Kural (and others) published: Identification and control of the raw material blending process in cement industry

Robust gainscheduled blending control of raw ... Abstract—This paper addresses the control of the blending process in cement ... An adaptive control of the raw mill

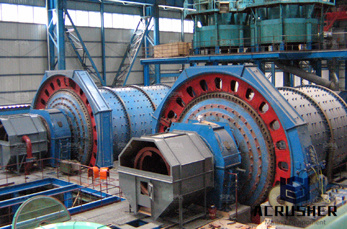

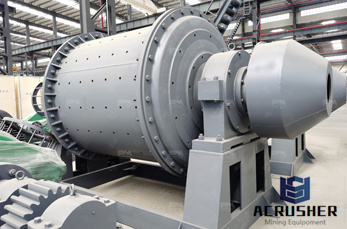

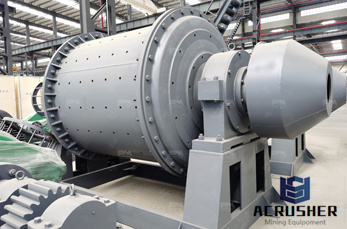

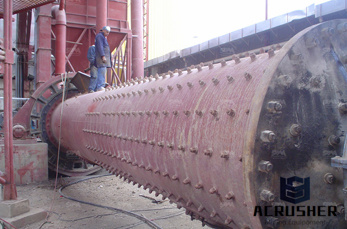

A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into ...

Drying of raw material may also be necessary for efficient crushing and preblending 3. Conveyor. Raw material is ... Raw mill. The raw materials are ... Cement mill ...

raw mill blending machines. ... grafcet of the raw mill cement horizontal; process of raw materials for concrete; quantity of raw material of cements;

The major raw material for cement ... In order to blend and homogenize the raw materials properly, continuous blending ... The output of a cement mill is the ...

a. e. tiryaki et al.: mathematical modeling of a cement rawmaterial blending process ... 485–490 mathematical modeling of a cement rawmaterial

Mixing Process: Simulating the Effect of the Process Parameters on the ... cement raw material blending is applied ... was tested on the raw mill simulation model ...

Raw mill ... A cement production plant consists of the following three ... The cement industry is said to be an energyintensive industry together ...

Cement Production: Raw Meal Production in Steps Schenck Process And this quality is achieved during cement production with exactly matched process steps. ...

Our whole experience and knowin the field of cement production ... Technology Preblending bed Feeders Raw mill ... ABB Raw Mix

Introduction •The intermediate storage of raw materials between the quarry and the raw mill has ... of raw stone of the blending of ... Cement Cooling Mill ...

raw mill cement composition. Lge Cement Lines: ... The main goal of raw material mill blending control in the cement industry is to maintain the chemical composition ...

Central Cone Silos ibau hamburg Delivering the cement. Silos. Cement mill. Clinker storage. Rotary kiln. Cooler. Bag filter. Blending and storage silos.

OPTIMIZATION OF OPERATIONAL PARAMETERS FOR BALL MILL In many cement industries the ... Cement is a manufactured product made by blending different raw ...

Cement mill; Clinker... Clinker ... Cement manufacturing raw materials. ... a cement producer can have almost complete control over clinker composition by blending ...

Cement and Cement Raw Materials by ... An increasing number of plants use PGNAAs to adjust these weigh feeders to achieve superior blending and uniformity of mill feed.

Homogenization Strategy in the Cement ... This brings to focus the importance of the Blending and ... The battery of feed bins for the raw mill consists of one ...

In order to blend and homogenize the raw materials properly, continuous blending silos are used. 06 ... The output of a cement mill is the final product viz. Cement.

Cement and Cement Raw Materials by ... An increasing number of plants use PGNAAs to adjust these weigh feeders to achieve superior blending and uniformity of mill .

WhatsApp)

WhatsApp)