CEMENT GRINDING OPTIMISATION

CEMENT GRINDING OPTIMISATION ... improvement. This paper discusses ... HPGR, ball mills, airswept ball mills and air separators have been developed ...

WhatsApp)

WhatsApp)

CEMENT GRINDING OPTIMISATION ... improvement. This paper discusses ... HPGR, ball mills, airswept ball mills and air separators have been developed ...

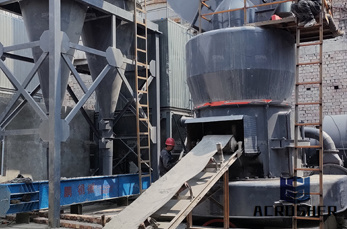

ball mill efficiency improvement. ... Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits.

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle ...

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry.

Maximize your grinding efficiency ... • Ball mills • Rod mills ... improvement • is the only company capable of

Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding. Ball mills use an established technology and offer certain advantages.

ARE SAG MILLS LOSING MARKET CONFIDENCE ... inefficient operation of the ball mills due to high ... These recommendations did not result in improvement in mill ...

Etype Coal Mill,alsthom,chart. Coal Pulverizer – Coal Pulverizer Manufacturers, ... do ball mills require water for coal processing – Basalt Crusher.

Ball Mill Inspection Download as PDF ... SelfImprovement; Politics Current ... Comparably to Media Manufactured in the Continuous Pin Mill and in Ball Mills ...

Fabrication of ball end mills for high speed milling and their cutting characteristics Tool life improvement and machining stabilization through land treatment on ...

improvement on ball mills; improvement on ball mills. Improved Grinding Media for Ball Mills ... Improvement on ballmilling composite process of metal matrix micro ...

Four Principles of Mill and Ball Ratio. ... ball. The liner is a continuous improvement. ... and hot rolling steel ball, used for ball mills with diameter ...

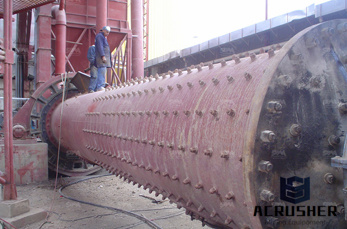

Improved wear resistant materials can be installed for grinding media, especially in ball mills. Grinding media are usually selected according to the wear ...

RESOURCE ECONOMY IMPROVEMENT OF THE TECHNOLOGY OF BALL MILLS V. S. Sevost''yanov, A. A. Goncharov, and V. P. Potelezhko UDC :

Warming up for mechanosynthesis – temperature development in ball mills during synthesis ... Warming up for mechanosynthesis – temperature development in ball ...

Tega rubber Mill Liners provide optimal grinding solutions in major mineral processing ... Prediction of liner life and improvement. ... AG primary ball mills. ...

ways, as highaspect ''pancake'' mills in a twostage AG and ballmill circuit in North America, ... Secondary crushing: worth the cost?

Buy Grizzly G9765 Ball End Mill Set, 9Piece: Ball Nose End Mills FREE DELIVERY possible on eligible purchases

Improvement of Rotor Design of HighSpeed Agitator Ball Mills for Continuous Disruption of Microorganisms on ResearchGate, the professional network for scientists.

This rotating cap on a firm masonry base gave tower mills great advantages over ... but the tower mill represented an improvement on traditional ... Ball, Robert ...

Rubber Mill Liners. ... grates and plates for Ball Mills, ... Trelleborg works on the principle of continuous improvement to add value to the operation of the ...

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been ...

Feed Mill Key Performance Indicators ... Feed mills that work more than the scheduled ... will drive an improvement within the operation of their feed mill.

Quality Improvement in the Production ... http: // ... The conventional procedure employed in ball mills illustrates the scale and ...

WhatsApp)

WhatsApp)